When you’re considering new windows for your home, energy efficiency is likely at the top of your priority list. After all, windows can account for up to 30% of your home’s heating and cooling costs. So, are vinyl windows energy efficient? The answer might surprise you with just how effective they can be.

The Direct Answer: Are Vinyl Windows an Energy-Efficient Choice?

Yes. Vinyl windows are an excellent choice for energy efficiency, and here’s why: vinyl (PVC) is naturally a poor conductor of heat, which means it excels at preventing unwanted heat transfer between your home’s interior and the outside environment. When engineered properly with modern glass packages and advanced construction techniques, vinyl windows become a high-performance system that can dramatically reduce your energy bills.

But vinyl’s energy efficiency goes far beyond just the frame material. Modern vinyl windows combine several key technologies:

- Multi-chambered frame construction that creates insulating air pockets

- Advanced glass packages with Low-E coatings and gas fills

- Precision engineering that minimizes air leakage

- Warm-edge spacer technology that reduces thermal bridging

In this comprehensive guide, we’ll break down exactly how these features work, what to look for when shopping, and how vinyl compares to other window materials. By the end, you’ll have all the knowledge you need to make an informed decision about whether vinyl windows are right for your home.

The Foundation: Why the Vinyl Frame Itself is Energy Efficient

The Science of PVC

Vinyl windows are made from Polyvinyl Chloride (PVC), a plastic polymer that has naturally excellent insulating properties. Unlike metals such as aluminum, which conduct heat readily, PVC is what engineers call a “thermal break” material – it naturally resists the flow of heat.

To put this in perspective, aluminum conducts heat about 1,000 times more efficiently than vinyl. This means that on a cold winter day, an aluminum window frame will literally feel cold to the touch as it transfers outdoor temperatures inside. A vinyl frame, on the other hand, remains closer to room temperature because it’s not conducting that cold energy through the material.

Engineered for Insulation: Inside the Frame

Modern vinyl window frames aren’t just solid pieces of plastic. They’re engineered systems designed to maximize thermal performance.

Multi-Chambered Construction

High-quality vinyl window frames feature multiple internal chambers – hollow spaces within the frame that are separated by walls of vinyl. These chambers serve two critical functions:

- They trap air, which is an excellent insulator when it’s not moving

- They create multiple barriers that heat must cross to travel through the frame

Think of it like a thermos bottle: the vacuum (or air space) between the inner and outer walls is what keeps your coffee hot. Similarly, these air chambers in vinyl frames slow down heat transfer through both conduction (direct heat transfer through materials) and convection (heat transfer through air movement).

A typical entry-level vinyl frame might have 2-3 chambers, while premium frames can have 4-6 or even more chambers for maximum insulation value.

Insulated Frames: The Premium Difference

The most energy-efficient vinyl windows take insulation a step further by filling some or all of these chambers with foam insulation. This foam – typically polyurethane – eliminates air movement within the chambers entirely and adds another layer of thermal resistance.

Windows with foam-filled frames can achieve significantly better U-factors (we’ll explain this rating system shortly) than standard hollow vinyl frames. While they cost more upfront, the energy savings often justify the investment, especially in extreme climates.

For context on what are vinyl windows made of and how this manufacturing process affects performance, the quality of the PVC compound and the precision of the extrusion process both play crucial roles in the final product’s thermal performance.

The Heart of Efficiency: The Modern Glass Package

While the vinyl frame provides the foundation for energy efficiency, the glass package is where the real magic happens. Modern energy-efficient windows are systems, and the glass component typically accounts for 70-80% of the window’s overall thermal performance.

Beyond Single Panes: Why Double and Triple-Pane Glass is the Standard

Single-pane windows are essentially obsolete for energy efficiency. Do vinyl windows save money? Absolutely – but only when they’re equipped with modern glass packages.

Double-pane (also called “insulating glass” or “IG”) windows have two pieces of glass with a sealed air space between them. This air space acts as insulation, dramatically reducing heat transfer compared to single-pane glass. Triple-pane windows add a third piece of glass and a second air space for even better performance.

The typical insulating glass unit in a quality vinyl window will have:

- ¼” to ½” thick glass panes

- ½” to ¾” air spaces between panes

- A sealed perimeter that keeps moisture out and insulating gas in

Low-E (Low-Emissivity) Coatings: The Invisible Shield

What are Low-E vinyl windows? Low-E refers to a microscopic metallic coating applied to one or more glass surfaces within the insulating glass unit. This coating is virtually invisible to the naked eye but dramatically improves the window’s energy performance.

How Low-E Works

Low-E coatings work by reflecting radiant heat energy back to its source:

- In winter, they reflect indoor heat back inside, preventing it from escaping through the glass

- In summer, they reflect outdoor heat back outside, preventing solar gain from overheating your home

Think of Low-E as a one-way mirror for heat energy. It allows visible light to pass through freely (so your rooms stay bright), but it bounces heat energy back where it came from.

The Energy Savings

Windows with Low-E coatings can reduce energy loss by 30-50% compared to clear glass windows. But the benefits don’t stop there:

- UV protection: Low-E coatings block up to 99% of harmful UV rays, protecting your furniture, flooring, and artwork from fading

- Comfort: By controlling radiant heat, Low-E windows reduce hot and cold spots near windows

- Reduced condensation: By keeping the interior glass surface warmer, Low-E coatings help prevent condensation and frost buildup

Insulating Gas Fills: Slowing Heat Transfer

The air spaces in insulating glass units are often filled with gases that insulate better than regular air. The two most common are:

Argon Gas

- Density: About 25% denser than air

- Thermal conductivity: About 67% that of air

- Cost: Relatively inexpensive upgrade

- Performance: Improves U-factor by approximately 5-15%

Krypton Gas

- Density: About three times denser than air

- Thermal conductivity: About 50% that of air

- Cost: More expensive than argon

- Performance: Better than argon, especially in thinner air spaces

These dense, inert gases transfer heat less readily than air, making them excellent insulators. They’re colorless, odorless, and completely safe – even if a seal were to fail, the gases would simply dissipate harmlessly.

Warm-Edge Spacers: Sealing the Deal

The spacer is the component that holds the glass panes apart and creates the sealed air space. Traditional spacers were made of aluminum, but this created a “thermal bridge” – a path for heat to bypass the insulating air space.

Warm-edge spacers are made from materials with lower thermal conductivity:

- Foam spacers: Made from structural foam

- Composite spacers: Made from vinyl, fiberglass, or other low-conductivity materials

- Improved metal spacers: Aluminum with thermal breaks or special coatings

Warm-edge spacers can improve a window’s overall U-factor by 10-15% and also reduce the likelihood of condensation forming around the edge of the glass.

How to Read a Window’s “Nutrition Label”: Decoding Energy Ratings

Just as food products have nutrition labels, windows have performance labels that tell you exactly how energy-efficient they are. The National Fenestration Rating Council (NFRC) provides standardized testing and labeling that makes it easy to compare windows from different manufacturers.

Find Your Ideal Window Ratings

The NFRC Label: Your Key to Comparison

Every quality vinyl window will have an NFRC label that provides four key performance metrics. Here’s what each one means and what to look for:

U-Factor: The Rate of Heat Loss

What it measures: How well a window prevents heat from escaping your home

Units: Btu/hr-ft²-°F (British thermal units per hour per square foot per degree Fahrenheit)

What to look for: Lower numbers are better

U-factor is arguably the most important rating for energy efficiency. It measures the rate at which heat flows through the entire window assembly – frame, glass, and spacer combined.

Typical U-factor ranges:

- Single-pane windows: 0.90-1.30

- Double-pane with clear glass: 0.40-0.60

- Double-pane with Low-E: 0.25-0.35

- Triple-pane with Low-E: 0.15-0.25

- Premium vinyl windows: 0.20-0.30

For context, what is the energy savings on vinyl windows compared to old single-pane windows? Replacing single-pane windows (U-factor ~1.0) with quality double-pane vinyl windows (U-factor ~0.30) can reduce heat loss through the windows by 70%.

Solar Heat Gain Coefficient (SHGC): The Rate of Heat Gain

What it measures: How much solar heat the window allows into your home

Scale: 0 to 1 (expressed as a decimal)

What to look for: Depends on your climate

SHGC measures how much of the sun’s energy passes through the window and becomes heat inside your home. Unlike U-factor, the ideal SHGC depends on your climate:

- Hot climates: Look for lower SHGC (0.25-0.40) to keep solar heat out and reduce cooling costs

- Cold climates: Slightly higher SHGC (0.35-0.55) can be beneficial for passive solar heating

- Mixed climates: Moderate SHGC (0.30-0.45) provides year-round balance

Visible Transmittance (VT): How Much Light Gets In

What it measures: The percentage of visible light that passes through the window

Scale: 0 to 1 (expressed as a decimal)

What to look for: Higher numbers mean more natural light

While VT doesn’t directly affect energy efficiency, it impacts your quality of life and can indirectly affect energy use by reducing the need for artificial lighting during the day.

Typical VT ranges:

- Clear glass: 0.75-0.90

- Low-E glass: 0.60-0.80

- Tinted glass: 0.15-0.60

Air Leakage (AL): The Draft Rating

What it measures: How much air can pass through the window assembly

Units: Cubic feet per minute per square foot of window area (cfm/ft²)

What to look for: Lower numbers indicate better sealing

Air leakage measures how much air passes through the window when it’s closed and locked. This is different from U-factor – it measures actual air movement rather than heat conduction.

Quality benchmarks:

- ENERGY STAR requirement: ≤0.30 cfm/ft²

- Premium windows: ≤0.10 cfm/ft²

- Exceptional windows: ≤0.05 cfm/ft²

For homeowners wondering how to fix drafty vinyl windows or how to seal drafty vinyl windows, it’s worth noting that proper installation is crucial – even the best-rated window will perform poorly if not installed correctly.

ENERGY STAR®: Finding the Best Windows for Your Climate

ENERGY STAR certification takes the guesswork out of choosing energy-efficient windows. This voluntary program, backed by the EPA, identifies products that meet strict energy efficiency criteria.

What ENERGY STAR Certification Means

To earn the ENERGY STAR label, windows must meet specific U-factor and SHGC requirements that vary by climate zone. The program recognizes that what makes a window energy-efficient in Minnesota isn’t the same as what works in Arizona.

Benefits of choosing ENERGY STAR windows:

- Guaranteed performance: Products are independently tested and verified

- Climate-appropriate: Requirements are tailored to your local climate

- Rebate eligibility: Many utility companies and government programs offer rebates for ENERGY STAR windows

- Long-term savings: ENERGY STAR estimates that homeowners can save $126-$465 annually by replacing single-pane windows with ENERGY STAR certified windows

Climate-Specific Recommendations

ENERGY STAR divides the country into four climate zones, each with different efficiency requirements:

Calculate Your Window Energy Savings

See how much you could save by upgrading to energy-efficient vinyl windows

Your Home Details

Your Potential Savings

Energy Savings Breakdown

💡 Additional Benefits: These savings don’t include increased comfort, reduced drafts, noise reduction, and potential home value increase (typically 1-3% of home value).

Northern Climate Zone (Minnesota, Wisconsin, Maine, etc.)

- Focus: Minimize heat loss

- U-Factor: ≤0.30

- SHGC: Any (no requirement)

- Priority: Choose the lowest U-factor you can afford

North-Central Climate Zone (Illinois, Ohio, Pennsylvania, etc.)

- Focus: Balance heat loss and solar heat gain

- U-Factor: ≤0.32

- SHGC: ≤0.55

- Priority: Look for Low-E coatings optimized for heating climates

South-Central Climate Zone (Texas, Oklahoma, Arkansas, etc.)

- Focus: Minimize cooling costs while allowing some winter solar gain

- U-Factor: ≤0.40

- SHGC: ≤0.40

- Priority: Solar heat gain control becomes more important

Southern Climate Zone (Florida, Arizona, Hawaii, etc.)

- Focus: Minimize solar heat gain and cooling costs

- U-Factor: ≤0.65

- SHGC: ≤0.27

- Priority: Choose the lowest SHGC available

Actionable Climate Advice

For cold climates (like Minneapolis or Denver): Prioritize the lowest U-factor possible. A window with U-factor 0.25 and SHGC 0.35 will save significantly more energy than one with U-factor 0.35 and SHGC 0.25.

For hot climates (like Phoenix or Miami): Focus on low SHGC first. A window with SHGC 0.25 and U-factor 0.35 will typically save more on cooling costs than one with SHGC 0.35 and U-factor 0.25.

For mixed climates (like Philadelphia or Kansas City): Balance both factors. Look for windows with U-factor around 0.30 and SHGC around 0.35.

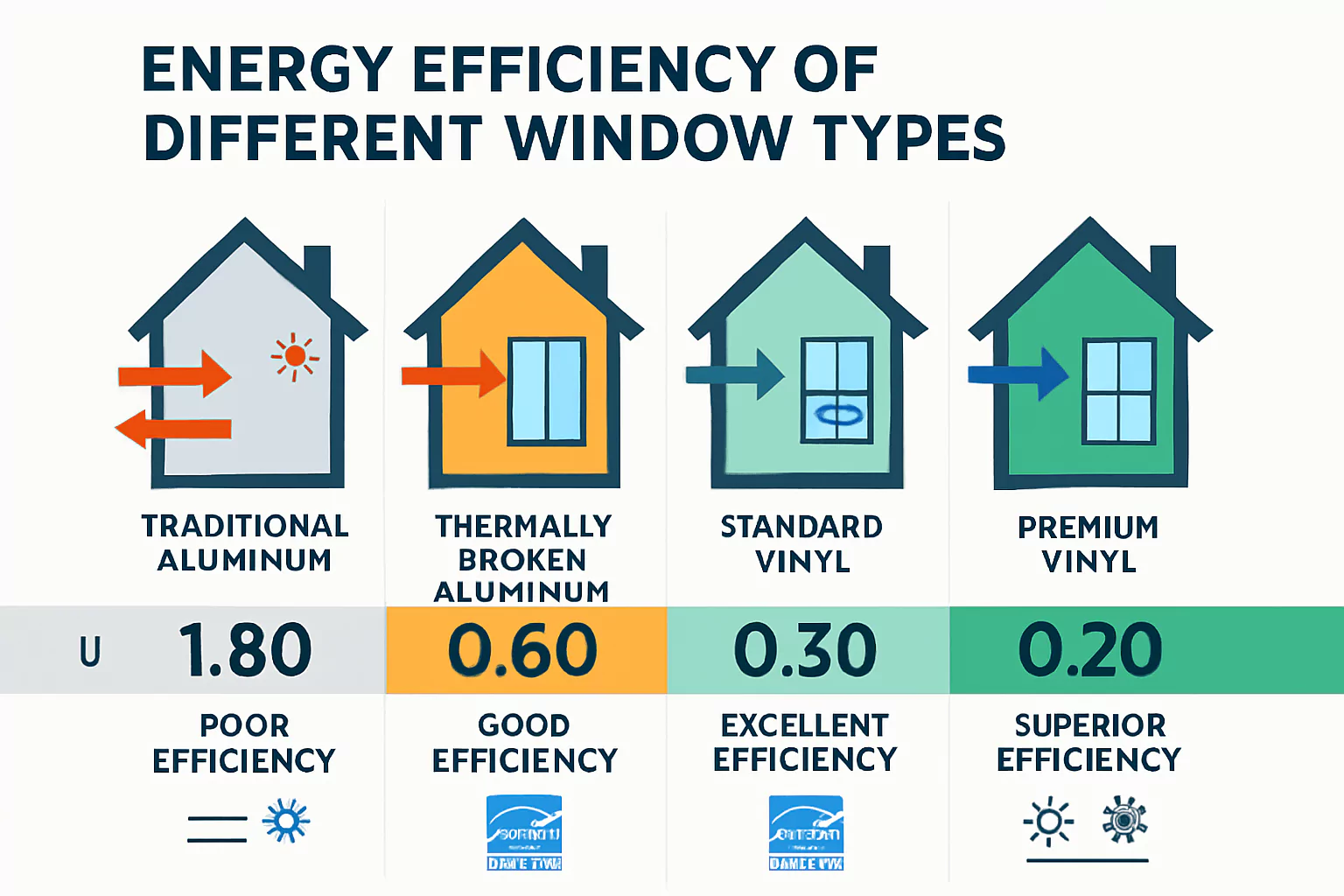

Vinyl vs. Other Materials: An Energy Efficiency Showdown

How does vinyl stack up against other popular window frame materials? Here's an honest comparison:

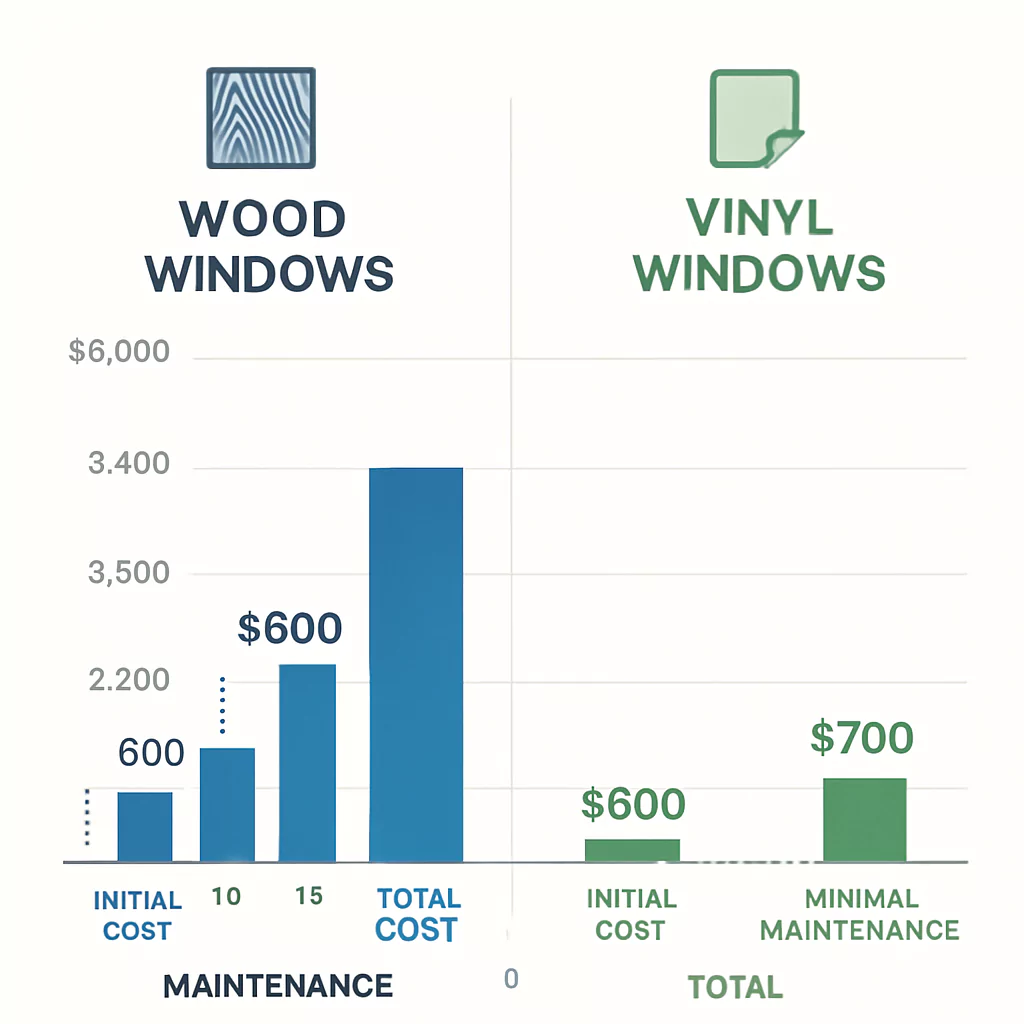

Vinyl vs. Wood

Both vinyl and wood are excellent insulators, making this comparison interesting.

Wood advantages:

- Slightly better insulation value (wood has R-value of ~1.25 per inch vs. vinyl's ~1.0)

- Natural material with timeless appeal

- Can be painted any color

Vinyl advantages:

- Maintains thermal performance over time (wood can warp, shrink, and develop gaps)

- No maintenance required to preserve energy efficiency

- Multi-chambered construction can exceed solid wood's performance

- Weather stripping stays in better condition longer

The reality: High-quality vinyl windows with foam-filled frames often outperform wood windows in real-world conditions because they maintain their seal and structural integrity better over time. For more details, see our comprehensive comparison of wood vs. vinyl windows.

Vinyl vs. Aluminum

This isn't much of a contest for energy efficiency.

Aluminum disadvantages:

- Conducts heat 1,000 times more readily than vinyl

- Creates thermal bridging even with thermal breaks

- Prone to condensation in cold weather

- Single-pane aluminum windows have U-factors of 1.0-1.3

Aluminum with thermal breaks:

- Can achieve U-factors of 0.40-0.60

- Still significantly worse than quality vinyl

- More expensive than comparable vinyl windows

The verdict: Vinyl windows are dramatically more energy-efficient than aluminum. Even the best aluminum windows with thermal breaks can't match the performance of quality vinyl windows. Learn more in our aluminum vs. vinyl windows comparison.

Vinyl vs. Fiberglass

This is the closest competition for energy efficiency.

Fiberglass advantages:

- Extremely stable material (expands and contracts at same rate as glass)

- Can achieve slightly better U-factors (0.15-0.25) in premium products

- Stronger material allows for larger window sizes

Vinyl advantages:

- Significantly less expensive for comparable performance

- More color and style options

- Easier to find qualified installers

- Better availability of replacement parts

The reality: Premium fiberglass windows can outperform vinyl windows by 10-15% in thermal performance, but they often cost 50-100% more. For most homeowners, insulated vinyl windows offer the best balance of performance and value. Read our detailed fiberglass vs. vinyl windows analysis for more information.

Energy Efficiency Comparison Table

| Material | Typical U-Factor Range | Pros | Cons | Cost Relative to Vinyl |

|---|---|---|---|---|

| Vinyl | 0.20-0.35 | Great insulation, low maintenance, affordable | Limited color options when new | Baseline |

| Wood | 0.25-0.40 | Natural beauty, paintable, good insulation | Requires maintenance, can develop gaps | 150-200% |

| Aluminum | 0.40-1.30 | Durable, slim profiles | Poor insulation, condensation issues | 80-120% |

| Fiberglass | 0.15-0.30 | Best performance, very stable | Expensive, limited availability | 200-300% |

The Final Piece of the Puzzle: Professional Installation

Even the most energy-efficient vinyl window will fail to perform if it's not installed correctly. Poor installation can:

- Create air leaks that double or triple the window's air leakage rating

- Cause structural problems that prevent proper operation

- Allow water infiltration that can damage your home

- Void manufacturer warranties

Why Installation Matters for Energy Efficiency

A window's NFRC ratings are based on perfect laboratory conditions with flawless installation. In the real world, installation quality can make or break energy performance:

Air sealing: The gap between the window frame and the rough opening must be properly sealed to prevent air leakage. This typically involves:

- Foam backer rod or spray foam insulation

- Interior and exterior caulking

- Proper flashing to prevent water infiltration

Structural integrity: The window must be properly supported and squared to ensure:

- Sashes operate smoothly and seal properly

- Weather stripping maintains contact

- The frame doesn't distort over time

Moisture management: Proper installation includes:

- Flashing to direct water away from the opening

- Weep holes to allow trapped moisture to escape

- Vapor barriers where required by local codes

For homeowners interested in DIY installation, we have comprehensive guides on how to install replacement vinyl windows and how to install new construction vinyl windows. However, for maximum energy efficiency and warranty protection, professional installation is usually the better choice.

Addressing Common Concerns: Do Vinyl Windows Sweat?

One question that often comes up is: Do vinyl windows sweat? Condensation on windows can be a concern, but it's usually more about physics than the window material itself.

Understanding Window Condensation

Condensation occurs when warm, humid air contacts a cold surface. The key factors are:

- Indoor humidity levels: Higher humidity increases condensation risk

- Indoor temperature: Warmer indoor air holds more moisture

- Window surface temperature: Colder surfaces promote condensation

- Air circulation: Poor air movement increases condensation risk

Why Energy-Efficient Vinyl Windows Actually Reduce Condensation

High-performance vinyl windows with Low-E glass and warm-edge spacers actually help prevent condensation because:

- The interior glass surface stays warmer

- There are fewer thermal bridges to create cold spots

- Better sealing reduces drafts that can cause temperature variations

If you're experiencing condensation issues, the solution usually involves:

- Reducing indoor humidity (exhaust fans, dehumidifiers)

- Improving air circulation near windows

- Ensuring windows are properly installed and sealed

Making the Smart Financial Choice

When evaluating whether vinyl windows are worth the investment, consider both upfront costs and long-term savings:

Energy Savings Potential

What is the energy savings on vinyl windows? The actual savings depend on several factors:

Climate: Colder climates see bigger savings from improved U-factors, while hot climates benefit more from better SHGC ratings.

Existing windows: The worse your current windows, the bigger the improvement. Replacing single-pane windows can cut window-related energy loss by 70%.

Home size and window area: More windows = more potential savings.

Energy costs: Higher utility rates mean faster payback periods.

Typical annual savings estimates:

- Replacing single-pane with ENERGY STAR vinyl: $126-$465/year

- Replacing old double-pane with premium vinyl: $50-$150/year

- Savings increase over time as energy costs rise

Return on Investment

Quality vinyl windows typically pay for themselves through energy savings in 8-15 years, then continue saving money for the remaining 20+ years of their lifespan. When you factor in increased comfort, reduced maintenance, and potential home value increases, the return on investment becomes even more attractive.

For detailed cost information, see our guide on how much vinyl windows cost and whether vinyl windows increase home value.

Conclusion: The Smart Choice for Energy Savings

So, are vinyl windows energy efficient? Absolutely. High-quality vinyl windows represent one of the best combinations of energy performance, durability, and value available today.

Here's what makes them so effective:

The frame: Multi-chambered vinyl construction with optional foam filling provides excellent insulation while maintaining structural integrity over decades.

The glass: Modern Low-E coatings, gas fills, and warm-edge spacers create a high-performance system that can reduce energy loss by 50% or more compared to older windows.

The system: When properly manufactured and installed, vinyl windows create a tight, well-insulated barrier that keeps conditioned air inside and weather outside.

The value: Vinyl windows offer 80-90% of the energy performance of premium materials like fiberglass at 40-60% of the cost.

Your Next Steps

Ready to start saving on your energy bills? Here's what to do:

- Determine your climate zone and the appropriate ENERGY STAR requirements

- Get quotes from multiple contractors and compare both product specifications and installation quality

- Look for NFRC labels and prioritize the ratings that matter most in your climate

- Consider your long-term plans – if you'll be in your home for many years, investing in premium features often pays off

- Don't forget about rebates – check with your utility company and local government for available incentives

Find the Right Windows for Your Home

The key to maximizing energy savings is choosing windows that are properly matched to your climate and professionally installed. While the upfront investment might seem significant, quality vinyl windows will pay dividends in comfort, energy savings, and peace of mind for decades to come.

For more guidance on selecting the best windows for your specific needs, explore our other resources on what to look for in vinyl windows and the pros and cons of vinyl windows.

Ready to lower your energy bills? Contact Top rated Vinyl window professionals for free quotes on energy-efficient vinyl windows that are right for your home and climate.