Walk through any modern residential neighborhood, and you’ll notice a common feature across homes built or renovated in the past few decades: vinyl windows. These fixtures have become the dominant choice in residential construction, accounting for over 70% of the window market in North America. But what exactly makes these windows so prevalent?

Vinyl windows are window frames made primarily from polyvinyl chloride (PVC), a synthetic plastic polymer known for its durability, insulation properties, and cost-effectiveness. Unlike traditional wood or aluminum windows, vinyl windows require minimal maintenance while providing excellent thermal efficiency—a combination that has fueled their widespread adoption.

This comprehensive guide will examine vinyl windows from the ground up—exploring their composition, how they’re manufactured, the various types available, and what factors distinguish quality vinyl windows from inferior options. Whether you’re researching for a future window replacement project or simply curious about the windows in your home, this article will provide the foundational knowledge you need.

For more specific information on whether vinyl windows might be the right choice for your home, check out our companion article on The Pros and Cons of Vinyl Windows.

The Core Material: What Are Vinyl Windows Made Of?

Typical Vinyl Window Frame Composition

- PVC Resin (Base Polymer)

- Stabilizers (UV Protection)

- Impact Modifiers

- Pigments (Color)

- Plasticizers/Other

Polyvinyl Chloride (PVC): The Foundation

At their core, vinyl windows are made from polyvinyl chloride (PVC), the same versatile plastic used in plumbing pipes, medical devices, and countless other applications. PVC is a thermoplastic polymer derived from two simple ingredients:

- Ethylene: A petroleum byproduct

- Chlorine: Derived from industrial salt processing

These components undergo polymerization—a chemical process that combines small molecules into long polymer chains—to create PVC resin, the base material for vinyl windows. This resin starts as a fine white powder that resembles flour in appearance.

Essential Additives for Performance

Raw PVC isn’t suitable for windows on its own—it requires several additives to enhance its performance characteristics:

Stabilizers

The most important additives in vinyl window formulations are stabilizers, particularly those that protect against ultraviolet (UV) degradation. Titanium dioxide is commonly used because it:

- Reflects UV radiation away from the polymer

- Prevents the vinyl from becoming brittle or yellowing over time

- Helps maintain the material’s structural integrity for decades

Impact Modifiers

To combat PVC’s natural rigidity and potential brittleness in cold temperatures, manufacturers add impact modifiers. These additives:

- Improve the material’s impact resistance

- Enhance flexibility without sacrificing strength

- Help prevent cracking during temperature fluctuations

Plasticizers

In standard vinyl applications, plasticizers increase flexibility by spacing out polymer chains. However, in window manufacturing, these are used minimally or completely avoided (in the case of uPVC) to maintain frame rigidity. When used, they:

- Improve workability during manufacturing

- Allow for smoother extrusion processes

- Can influence the window’s long-term performance

Pigments

Pigments give vinyl windows their color. Most vinyl windows are white or light-colored because:

- Lighter colors reflect heat rather than absorb it

- This reduces thermal expansion and contraction

- It minimizes potential warping or seal failures

Darker colored vinyl windows typically require special formulations with additional stabilizers and more advanced engineering to prevent heat-related issues.

Virgin Vinyl vs. Recycled Vinyl

Not all vinyl used in window manufacturing is the same. The industry distinguishes between two main types:

Virgin Vinyl

Virgin vinyl refers to PVC material made entirely from new, unused resin. Windows made with virgin vinyl typically offer:

- More consistent quality control

- Better long-term color stability

- Enhanced weathering characteristics

- Stronger welded corners

- Superior resistance to discoloration

Recycled Vinyl

Recycled vinyl incorporates reclaimed PVC material from post-industrial or post-consumer sources. While environmentally beneficial, it comes with certain considerations:

- May have slightly less consistent performance

- Often used in less visible or structurally critical parts

- Can be more susceptible to quality variations

- May offer cost advantages

- Reduces environmental impact through reuse

Many premium window manufacturers use primarily virgin vinyl for exterior surfaces (which face the harshest conditions) while incorporating recycled content in interior components or non-critical areas.

PVC vs. Vinyl vs. uPVC: Understanding the Terminology

The window industry uses several related terms that can cause confusion:

- PVC (Polyvinyl Chloride): The basic chemical name for the plastic polymer

- Vinyl: The common consumer-friendly term for PVC products in North America

- uPVC (Unplasticized PVC): The term common in Europe and increasingly in the US

The key difference lies in the “unplasticized” designation of uPVC, which means:

- Minimal to no plasticizers are added to the formulation

- The resulting material is more rigid and durable

- It’s particularly suitable for structural applications like window frames

In practical terms, most modern vinyl windows are actually made from uPVC, even if they’re simply marketed as “vinyl windows” in North America. The rigidity of uPVC makes it ideal for maintaining window dimensions and preventing warping.

The Manufacturing Process: From Resin to Window Frame

Raw Material Preparation

The journey from raw materials to finished windows begins with precise formulation:

- PVC resin is measured and combined with the exact proportions of additives

- These components are thoroughly blended in high-speed mixers

- The resulting compound is heated until it reaches a homogeneous consistency

- Quality checks ensure the mixture meets specification standards

Extrusion

The heart of vinyl window manufacturing is the extrusion process:

- The PVC compound is fed into an extruder—essentially a large, industrial machine with a heated barrel and rotating screw

- Inside the extruder, the material is heated to approximately 350-400°F (175-205°C), turning it into a malleable, dough-like consistency

- The softened PVC is forced through a die—a precisely engineered metal template that gives the vinyl its profile shape

- As it emerges from the die, the hot vinyl passes through a series of cooling tanks or chambers

- The cooling stabilizes the material, setting it into its final shape

What makes vinyl window frames special is their multi-chambered design. The extrusion dies create hollow chambers within the profiles that:

- Trap air for improved insulation

- Provide structural rigidity without excessive weight

- Allow for internal reinforcement when needed

- Create pathways for water drainage

Assembly

Once the profiles are extruded and cut to precise lengths, they move to assembly:

- Frame components are mitered (cut at angles) at the corners

- The mitered pieces are fusion-welded together—a process that heats the vinyl until it melts and joins the pieces as one

- After cooling, the welded corners are cleaned and finished to remove excess material

- The fusion-welding process creates corners that are actually stronger than the original vinyl material

With the basic frame assembled, additional components are integrated:

- Weatherstripping is inserted into dedicated channels

- Hardware like locks, handles, and hinges are attached

- Reinforcement (typically aluminum or steel) is added where needed

- Glass packages are installed and sealed into the sashes

Finishing and Quality Control

Before leaving the factory, vinyl windows undergo rigorous testing:

- Air and water infiltration tests ensure proper sealing

- Operation tests check for smooth functionality

- Visual inspections identify any cosmetic defects

- Dimensional verification confirms exact specifications

This multi-step manufacturing process creates a complete window unit ready for installation. The precision of modern manufacturing allows for consistent quality at scale, which is one reason vinyl windows have become so cost-effective.

For a deeper dive into how various window materials compare in terms of construction and benefits, see our article on Vinyl vs. Other Window Materials.

Key Components of a Vinyl Window

The Frame

The frame is the outermost structure of the window that attaches to the house opening. Modern vinyl frames feature:

- Multi-chambered profiles: Interior walls create separate air chambers for thermal efficiency

- Fusion-welded corners: Heat-welded corner joints that are stronger than mechanical fasteners

- Integrated nailing fins (in new construction models): Extensions that secure the window to the house framing

- Water management systems: Weep holes and drainage channels that direct moisture away

Higher-quality vinyl windows feature more chambers within their frames—typically 3-5 chambers, though premium options may have up to 7 chambers for maximum insulation.

Sashes

The sash is the movable part of the window that holds the glass. In a double-hung window, there are two sashes (upper and lower); in a casement window, the entire sash swings open. Sashes include:

- Sash frames: The vinyl structure surrounding the glass

- Glazing stops: Components that secure the glass within the sash

- Tilt mechanisms (in double-hung windows): Hardware allowing the sash to tilt inward for cleaning

- Reinforcement: Metal supports within larger sashes to prevent sagging

Glazing

The glazing or glass package is arguably the most important component for energy efficiency:

- Insulated Glass Units (IGUs): Two or three panes of glass sealed together with a spacer around the perimeter

- Spacers: Materials that separate the glass panes and create a sealed air space

- Gas fills: Argon or krypton gas between panes that insulate better than air

- Low-E coatings: Microscopic layers of metal or metallic oxide that reflect infrared energy (heat)

Modern vinyl windows almost exclusively use double-pane glass as a minimum standard, with triple-pane options available for enhanced efficiency in colder climates.

Hardware

The hardware components enable operation and security:

- Locks and keepers: Secure the window when closed

- Balance systems (in double-hung windows): Counter the weight of the sash for easier operation

- Hinges (in casement windows): Allow the sash to swing open

- Handles and cranks: Provide the means to operate the window

- Limit stops: Restrict how far a window can open (a safety feature)

Quality hardware is critical to long-term performance—premium vinyl windows use corrosion-resistant materials like stainless steel or brass-coated components.

Weatherstripping

Weatherstripping creates the seal between moving parts of the window:

- Compression weatherstripping: Foam or rubber material that compresses when the window closes

- Brush seals: Fine bristles that block air infiltration while allowing movement

- Fin seals: Flexible plastic fins that create multiple barriers against air

Better-quality vinyl windows feature multiple layers of weatherstripping and often use different types in combination for optimal sealing.

Types of Vinyl Windows and Related Concepts

Standard Vinyl Windows

Standard vinyl windows represent the most common type found in homes today. These windows:

- Are made primarily or entirely of extruded PVC

- Feature hollow or multi-chambered frames for insulation

- Come in various operational styles (double-hung, slider, casement, etc.)

- Offer good energy efficiency at competitive price points

Most vinyl windows sold in home improvement stores and installed by window companies fall into this category.

Composite Vinyl Windows

Composite vinyl windows combine vinyl with other materials to enhance performance:

- Vinyl-wood composites: Blend wood fibers with vinyl for improved strength and appearance

- Fiberglass-reinforced vinyl: Incorporate fiberglass strands or components for structural integrity

- Structural foam-filled vinyl: Use foam inserts to increase insulation and rigidity

These hybrid approaches aim to address some of vinyl’s limitations while maintaining its advantages. They typically command higher prices but offer enhanced performance characteristics.

Engineered Vinyl Windows

Engineered vinyl windows refer to premium vinyl products with specialized enhancements:

- Impact-resistant designs: Reinforced frames and laminated glass for hurricane zones

- Noise reduction packages: Modified frame designs and specialized glass for sound attenuation

- Security-focused options: Enhanced locking systems and stronger components

- Extreme weather performance: Specialized formulations for very hot or cold climates

These windows are designed for specific performance requirements beyond standard expectations.

Vinyl-Clad Windows

Vinyl-clad windows are fundamentally different from true vinyl windows:

- They feature a core material (typically wood) with a vinyl exterior covering

- The interior surface is usually the core material (often wood) for aesthetic appeal

- They combine the low-maintenance exterior of vinyl with the warmth and character of wood interiors

- They are generally more expensive than all-vinyl windows

- Their performance differs from all-vinyl options, particularly in terms of expansion/contraction

It’s important not to confuse vinyl-clad windows with all-vinyl products, as their construction, price points, and performance characteristics vary significantly.

For a comprehensive breakdown of all window styles available in vinyl, see our Ultimate Vinyl Window Buyer’s Guide.

Performance, Benefits, and Drawbacks of Vinyl Windows

Key Benefits

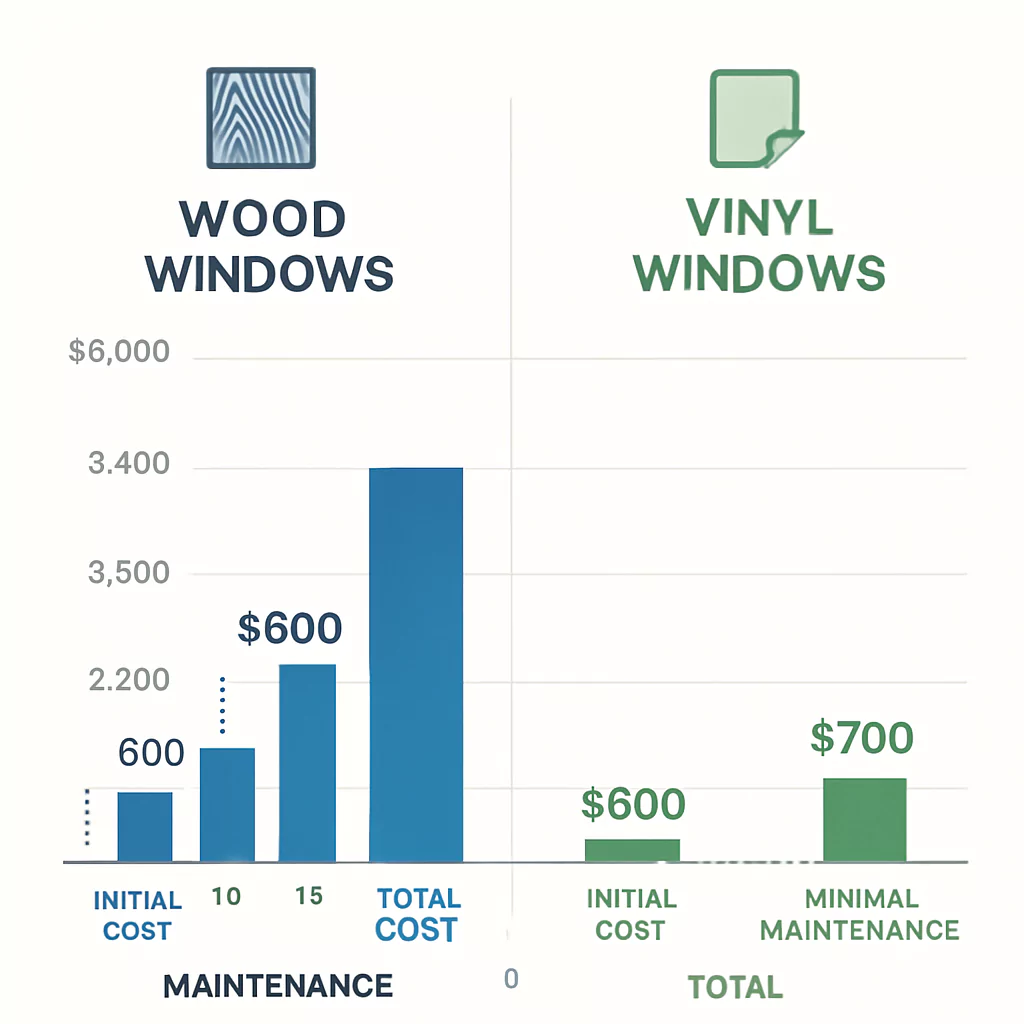

Affordability

One of vinyl’s most compelling advantages is its cost-effectiveness:

- Generally 10-30% less expensive than comparable wood windows

- Similar or lower cost than quality aluminum options

- Excellent value considering performance and longevity

- Lower lifetime cost when factoring in minimal maintenance requirements

Low Maintenance

Vinyl windows are prized for being virtually maintenance-free:

- No painting or staining required—ever

- Cleaning requires only mild soap and water

- No risk of rot, rust, or corrosion

- Impervious to termites and other pests

- Won’t swell, crack, or peel under normal conditions

This maintenance advantage is particularly valuable for hard-to-reach windows or homes in harsh climates.

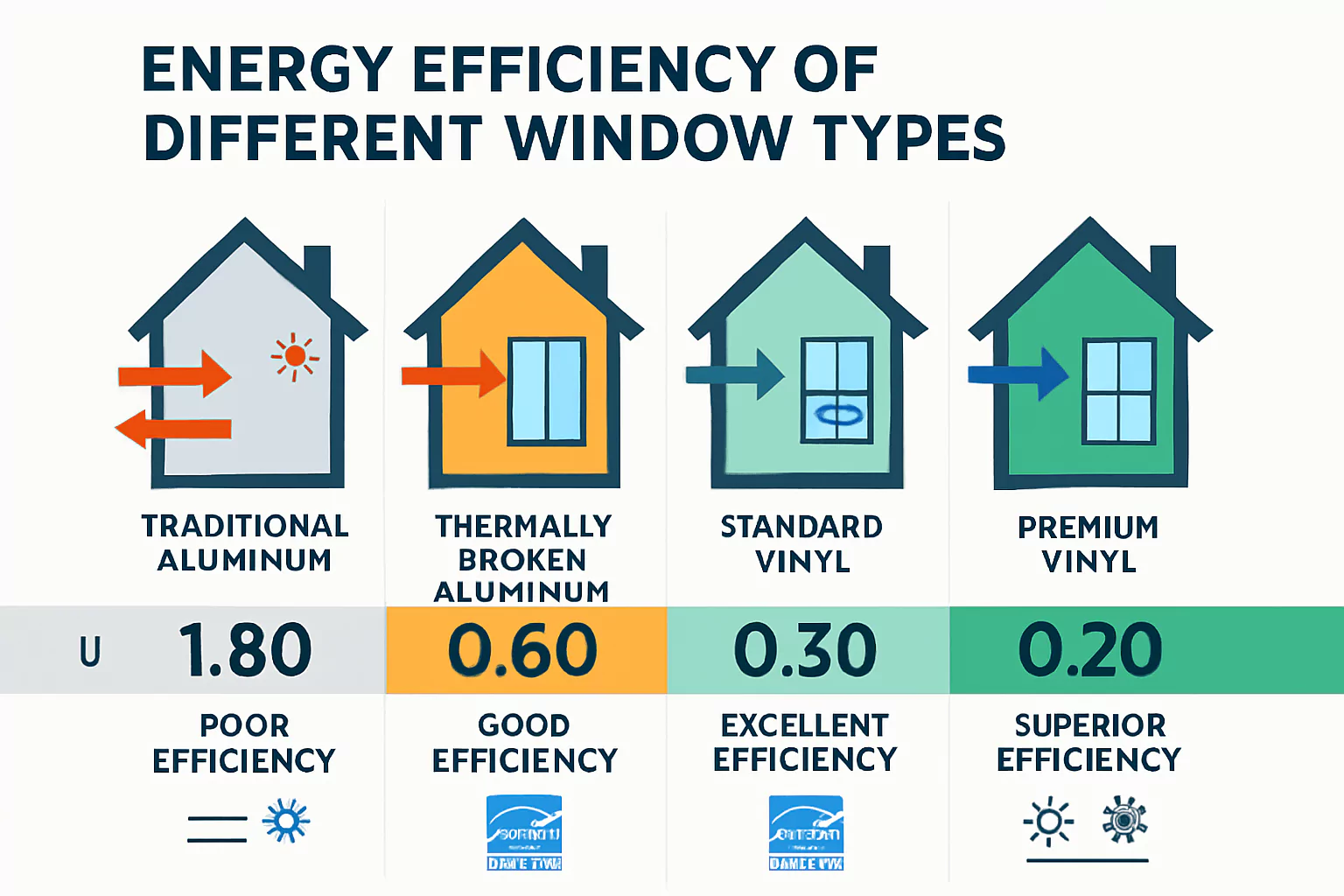

Energy Efficiency

Vinyl’s natural properties make it an excellent insulator:

- Low thermal conductivity (transfers very little heat or cold)

- Multi-chambered profiles trap air for additional insulation

- Compatible with high-performance glazing options

- Can help reduce heating and cooling costs significantly

- Helps homes qualify for ENERGY STAR® certification

Durability

Modern vinyl windows offer impressive longevity:

- Typical lifespan of 20-40 years depending on quality and conditions

- Resistant to moisture damage

- Won’t corrode in coastal environments

- Color throughout the material (not just surface treatment)

- UV stabilizers prevent degradation from sun exposure

Variety

Today’s vinyl windows come in numerous styles and colors:

- All traditional operating styles (double-hung, casement, awning, slider, etc.)

- Fixed and specialty shapes

- Standard colors including white, almond, tan, and clay

- Premium colors and woodgrain finishes in higher-end lines

- Custom sizes to fit nearly any opening

Potential Drawbacks

For a balanced view, it’s important to acknowledge vinyl’s limitations:

For a more in-depth look at these considerations, see our article on The Pros and Cons of Vinyl Windows.

Making an Informed Choice: What to Look For

Quality Indicators

Not all vinyl windows are created equal. Look for these markers of quality:

- VSI Certification: The Vinyl Siding Institute certifies manufacturers who meet specific quality standards

- Frame Thickness: Wall thickness of at least 0.060-0.080 inches indicates durability

- Chamber Design: More internal chambers generally mean better insulation

- Corner Construction: Fusion-welded corners outperform mechanically fastened ones

- Hardware Quality: Metal (rather than plastic) components suggest attention to detail

Virgin vs. Recycled Vinyl

Understanding the vinyl composition helps assess long-term performance:

- Premium windows use virgin vinyl for exterior-facing components

- Recycled content is acceptable for non-critical or interior components

- All-recycled vinyl frames may have shorter lifespans

- Manufacturers should be transparent about their materials

Energy Efficiency Ratings

The National Fenestration Rating Council (NFRC) label provides standardized performance metrics:

- U-Factor: How well the window prevents heat loss (lower is better, typically 0.25-0.35 for good vinyl windows)

- Solar Heat Gain Coefficient (SHGC): How much solar radiation passes through (lower numbers reduce cooling costs in hot climates)

- Air Leakage: Measure of air infiltration (lower is better)

- Visible Transmittance: Amount of light that passes through

- Condensation Resistance: Ability to resist water buildup (higher is better)

Look for ENERGY STAR® certification appropriate for your climate zone.

Warranty

A strong warranty indicates manufacturer confidence:

- Length: Better vinyl windows offer 20+ year or lifetime coverage on frames

- Transferability: Ability to transfer warranty to new homeowners adds value

- Coverage: Comprehensive warranties cover materials, hardware, and seals

- Limitations: Understand what might void the warranty (e.g., improper installation)

For detailed information on what to expect from warranties, see our article on Understanding Vinyl Window Warranties.

Installation

Even the best vinyl window will underperform if improperly installed:

- Professional installation is strongly recommended

- Proper flashing and sealing are critical to prevent water intrusion

- Expansion space must accommodate vinyl’s natural movement

- Installation errors are responsible for most window performance problems

For guidance on the installation process, see our article on Professional Window Installation.

Conclusion: The Role of Vinyl Windows in Modern Homes

Vinyl windows have revolutionized the window industry by offering an optimal balance of performance, price, and practicality. Understanding what vinyl windows are made of—from their PVC core to specialized additives—helps explain their dominant market position and enduring popularity.

These windows excel in situations where energy efficiency, low maintenance, and value are priorities. They’re particularly well-suited for:

- New construction where budget efficiency matters

- Replacement projects where minimal upkeep is desired

- Homes in moderate climates where thermal efficiency is valuable

- Coastal areas where corrosion resistance is important

While no building material is perfect for every application, vinyl windows have earned their place as the standard choice for most residential window applications today. By understanding their composition, manufacturing, and key performance factors, homeowners can make informed decisions about whether vinyl windows are the right choice for their specific needs.

If you’re considering vinyl windows for your home, take time to:

- Research reputable manufacturers

- Compare specific models and their NFRC ratings

- Request samples to assess quality in person

- Obtain multiple quotes from qualified installers

- Review warranty terms carefully

With the right information and attention to quality, vinyl windows can provide decades of comfortable, efficient, and trouble-free service in your home.

Looking for specific guidance on selecting the best vinyl windows for your needs? Check out our comprehensive Ultimate Vinyl Window Buyer’s Guide for detailed selection advice.